Projects & Team experience

Engineering, Design, and Manufacturing Projects

Some of the most enjoyable courses and experiences in my Stanford career have been through the project courses offered at Stanford's Product Realization Lab. These courses are focused on building strong technical skills while at the same time improving design thinking as well. I especially enjoy working with groups to accomplish successful designs.

If you're curious to see the products of these experiences, please take a look at the projects below.

If you're curious to see the products of these experiences, please take a look at the projects below.

ME 310: Product-Based Engineering Design, Innovation, and Development

|

The teams in ME 310 are partnered with a corporate sponsor and an international team to explore a broad topic within the corporations area of interest.

Our task was to use ambient communication to help improve the driver/passenger team dynamic in a fully autonomous vehicle move from a master slave relationship to a more teammate relationship. After two quarters of need finding and prototyping we arrived at the conclusion that communicating the autonomous vehicle's perception and intention was the best place to attack. To facilitate this communication we built a foot pedal to provide pre-haptic feedback to the passenger and a perception system mapping the input from sensors to light pars around the passenger. We envisioned the ambient communication of this information would help the passenger to anthropomorphize and more easily trust the vehicle by subconsciously building narrative reason for the vehicle's actions. In testing the reaction was in line with our goals and we were extremely happy with the results. Commercial Final Report |

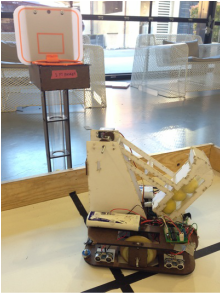

ME 210: Introduction to Mechatronics

|

The final project for this to have out miniature basketball player score three balls into the basket at the other end of our playing court. After playing with encoders, line followers, and IR sensors we settled on using ultrasonic sensors to work our way across the court to score our baskets by dunking all 3 balls at once.

Project Website |

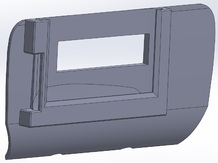

ME 318: Computer-Aided product creation

|

ME 318 is one of the more advanced design and manufacturing courses at Stanford. In this course students are taught the intricacies of SolidWorks and GibbsCAM and are then taught how to operate one of the Haas Mills.

For the final project, students are allowed to choose any type of product that they would like to make, so long as it includes 3D machining. At the time I was fascinated by how beautiful planetary gears were. I knew that I was going to use them in my project, but I wasn't sure how until I realized just where the names for the sun gear and planet gears came from. My Heliocentric Solar System features 3D printed planets and a sun cut by a CNC Mill. I also managed to fit in some wood working in this project by making the base. |

|

One of the required projects during my quarter was to create a bottle opener that could open both twist off and pop off bottles. Since this was a couple months after the 2013 Rose Bowl win I created a bottle opener that would commemorate one of my proudest achievements. It is only fitting that the bottle opener itself is one of my proudest achievements as well.

|

ME 203: Design and Manufacturing

|

ME 203 is Stanford's introductory course to design and manufacturing. It teaches students the basics of how to safely use the machines in the shop. Most students choose to specialize in one machine but I chose to try and use as many in my project as possible. Unfortunately there was not a reasonable way to work casting in the time allotted and they would not let me help with the powder-coating.

I settled on an old fashioned apple cider press because I am a 5th generation apple farmer and we are starting to explore the heirloom cider business. I eventually settled on the simple design you see because it allowed me to have a truly beautifully finished product whose every shining service could be observed while it worked. |

Me 113: Mechanical Engineering Design

|

ME 113 is a capstone design course in which teams of four are partnered with a company to work on a quarter long project of their choosing. For my teams's design project we were tasked with making the interior of a Ford Mustang more modular to improve the owner experience. We came to the conclusion that the reason that many cars feel old is that consumer electronics that are vital to the cars sound and electronics system are on a much quicker cycle. The consumer electronics market is typically on an 18 month cycle where as most automobiles are on a five year cycle. This means that by the time a car is sold its electronics are nearly guaranteed to be outdated.

We came up two solutions for this problem. The first was to create 3D printable template that could be printed to hold a tablet or phone or any device that is desired. It could then be easily installed in place of the car stereo to allow for the driver to change the electronics with the pace of consumer electronics. Our other solution was to create a universal holder that conformed to any surface. We accomplished this by using jamming granular material in the form of coffee in a latex skin. Once the device is placed, the air is evacuated causing the granules to clump or jam together and become rigid. This created a remarkably strong grip that worked with any device that fit was smaller than the front surface of the holder. |

Our report summary is up on the Ford Open XC site and I encourage anyone who is interested in this project to contact me as we are currently exploring this topic.

Ford Open XC Stanford Senior Design Project

Ford Open XC Stanford Senior Design Project

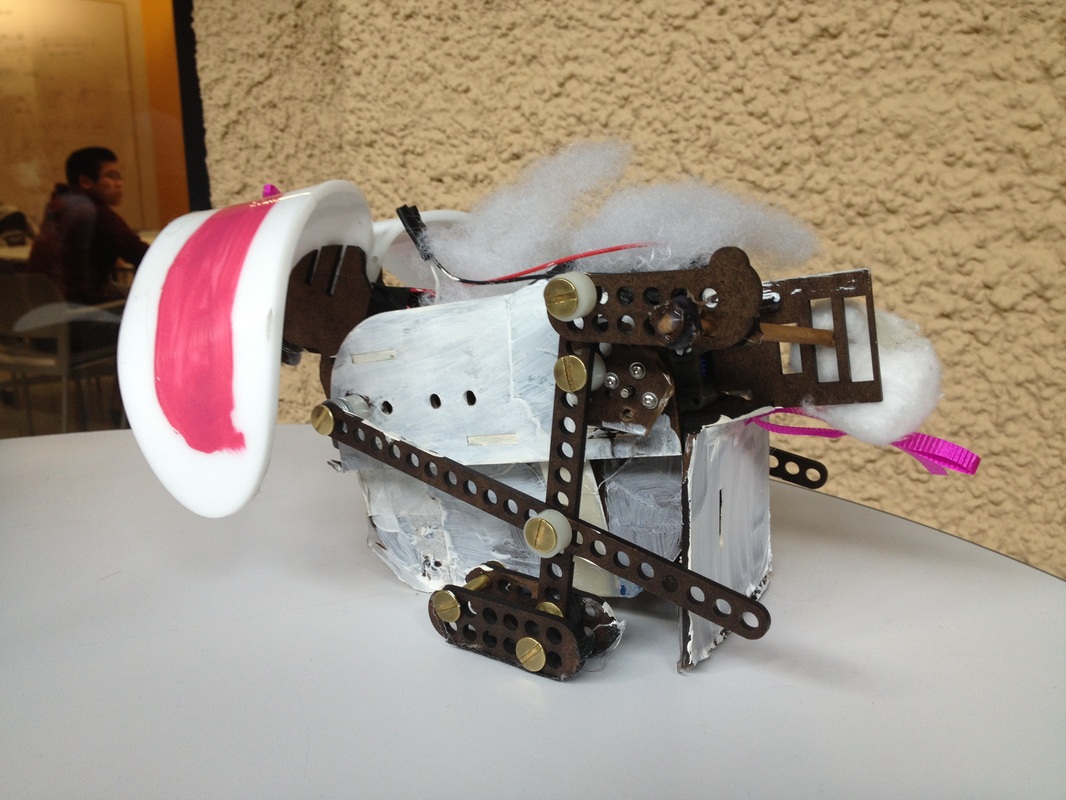

Me 112: Mechanical systems design

|

The final assignment for this course was to produce a robot that was capable of moving with a rabbit like motion while "hopping" up a ramp and wiggling its ears nose or tail. In this project we incorporated the knowledge of gear ratios, motor specifications, and linkages to produce a slightly terrifying robotic rabbit.

|

ME 140: Advanced Thermal Systems

|

The final project for the capstone thermal sciences course is to design, build, test, and then iterate a hybrid rocket engine. In order to manufacture the fuel grain quickly with the needed tolerance, I used an easily repeatable CNC Mill setup to make the manufacturing much easier. In addition to using the CNC Mill, I also turned the HDPE fuel grain to the proper diameter turned the graphite nozzle to within 0.001" accuracy.

|

me 219: the Magic of materials and Manufacturing

|

As part of this course on material properties and manufacturing methods, my group was tasked with exploring the material properties the relatively mundane birch tree. Although birch dopes not hold any particularly unique physical characteristics beyond being easy to steam bend, it holds some very strong emotional connections across cultures. Birch is used in anything from canoes, to beer, to medicine and is very uniquely revered by Native American and Russian cultures specifically for exactly those reasons. We showcased birch's unique emotional connections by steam bending birch into beer koozies for birch beer to drink around a smooth burning birch fire while listening to a Russian poem about the tree that means so much to so many.

|

me 131a: Heat transfer

|

As part of the heat transfer course we created a model whose goal as to accurately predict the behavior of a heat sink that we actually created. To get the most accurate results we decided to take extra careful steps in manufacturing such as creating a sheath to prevent the pins from buckling during the press fitting process and practicing extensively to develop accurate practices with the lathe.

|